This newsletter has English and Spanish versions. To choose which language you receive, visit your settings on Substack, find this newsletter under Subscriptions, and select the language(s) you want.

Leer en español aquí.

Indigo, madder and weld are known as “ancient primaries” because they have stood the test of time as exceptional sources of blue, red and yellow all over the world. I had the opportunity to dye with all three of them in July. I wrote about madder and weld last month and now I’m going to share my experiences with indigo.

Every time I make a new indigo vat I’m a little nervous about it. At the very least, indigo is expensive, so when I mess it up I’m losing all the money I spent on ingredients and possibly ruining some fiber too. After an indigo vat I made earlier this year ended up failing spectacularly, I was extra anxious to make a vat as soon as I got to Ohio, especially since I had already agreed to teach two indigo workshops. So I spent the 4th of July weekend dyeing indigo at my family’s cabin. I didn’t change anything about my process except the location, but I think the ambient temperature (it was summer, so the vat didn’t get too cold at night) and just having the time, space and help (thanks Mom!) to plan things out a little better made a difference1.

While I still don’t feel like an indigo expert, the successful vat helped me go in and teach the indigo workshops with confidence. It was the biggest vat I’ve ever made! We got great color results, I realized I know more than I thought I did about indigo, and overall we had a great time. It’s definitely a more complicated workshop than bundle dyeing in terms of set up logistics and potential messes but I hope I have the chance to repeat it.

While I was focused on the indigo vat, plus madder and weld and my bundle dyeing workshop, the fresh indigo was growing in the backyard. Last year’s plants thrived immediately, but this year they experienced a few more setbacks: my parents’ cat tried to eat the seedlings (he succeeded with some of them), there wasn’t a lot of rain this spring, and the wildfire smoke that affected the area probably didn’t help them either. Wanting to give them as much time as possible to grow, I waited until the very end of my time in Ohio to harvest.

Last year I dyed fresh indigo using the salt rub method and the color that resulted is one of my favorites I’ve ever dyed- a delicate turquoise blue. So this year I was hoping to repeat that result with the same process. The salt rub method is easy to do- all you need are the leaves, some salt, a bowl to work in, and a bit of patience.

All species of indigo plants contain a substance called indican and an enzyme which are kept separate in the leaves until the cell is ruptured- with the salt rub method, this happens by literally breaking up the leaves with your hands and a bit of salt. The indican and enzyme combine to form indoxyl, which then combines with oxygen to produce indigotin, the substance that makes indigo blue. Working with fresh indigo means making this reaction happen with your own hands!2

Of course if you are doing this process with wool there is a high danger of felting, a lesson I learned last year but apparently not well enough because it happened again. The base I brought to dye with fresh indigo felts pretty easily, it turns out, so this method and fiber were not a good match. Fortunately, I also had a bunch of silk scarves to work with as well. I worked the fresh leaves directly with the scarves to create the indigotin reaction, then once it was more of a liquid mash I squeezed the dye out onto the yarn. This prevented felting but left me with highly variegated color. Next year I’ll try a different fresh indigo method for wool. The scarves, though, are stunning. Each one came out with a unique pattern from the direct contact with the leaves. At first this wasn’t on purpose, but as I saw what was happening I tried to manipulate the scarves evenly so the effect was present all over the fabric.

Finally, I tried to reuse the indigo leaves and liquid by doing an indirubin extraction (once again from a Dogwood Dyer tutorial about how to get a whole rainbow of colors from fresh indigo). Indirubin (dye compound that can be created in all indigo plants that gives the blue its purplish tone) can be coaxed from fresh indigo leftovers with a heated alkaline extraction (I used some ground up antacids for calcium carbonate) that is supposed to give a grayish mauve color. Mine turned out a greenish gray that slowly oxidized to a purplish gray… but definitely gray. Not purple or mauve. Since I only learned about this dye method recently and it was my first time trying it, I don’t really know why I didn’t get more purple. Maybe the pH needed to be a little higher? The experiment was fun and I love being able to reuse dye baths, and the color is interesting but I probably wouldn’t wear a scarf that was only this color so I’ll continue working on it.

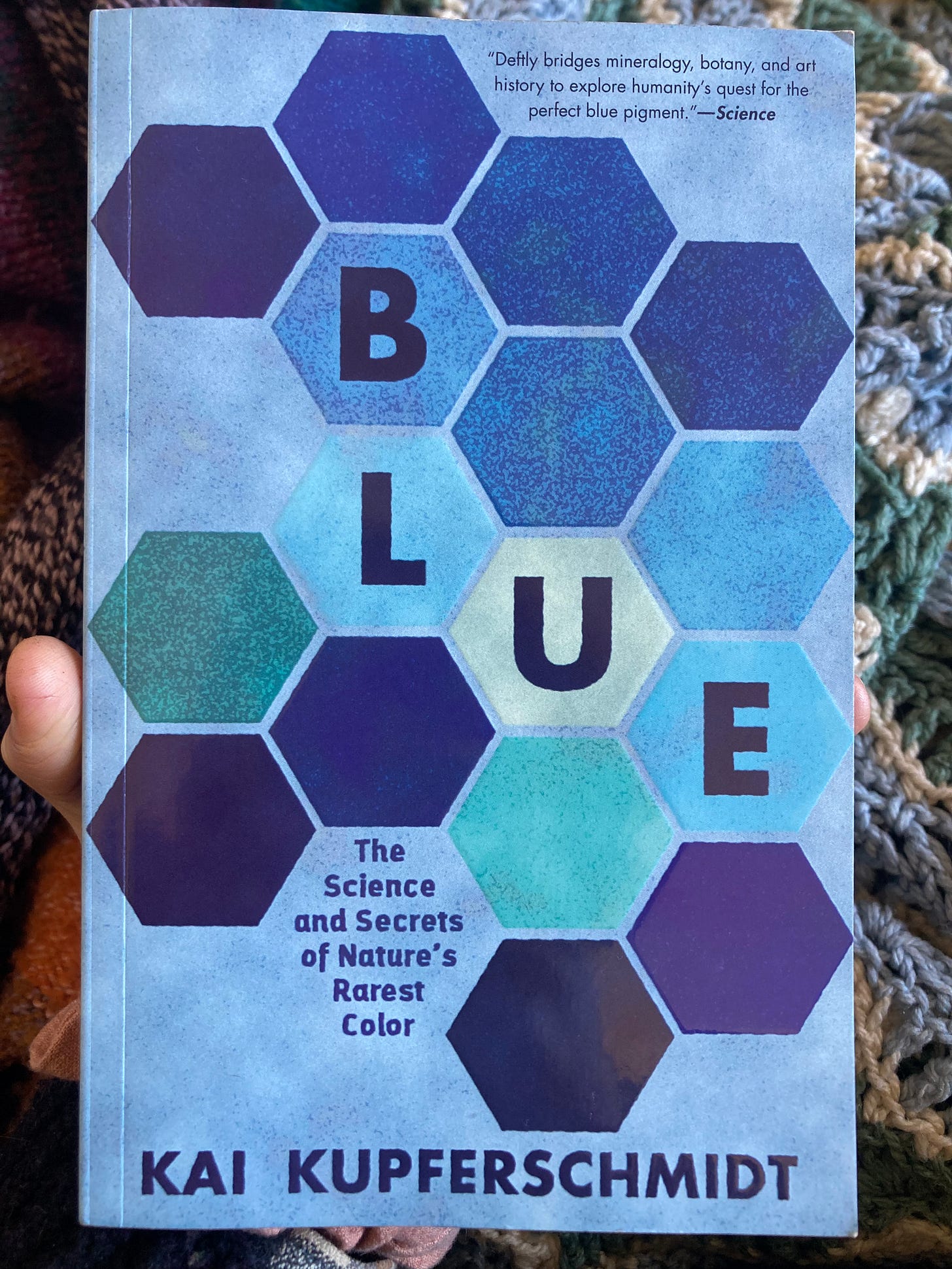

One thing I didn’t anticipate when I first started dyeing is how it would awaken an interest in science I never knew I had! I’m constantly thinking about what exactly color is, what chemicals or minerals or reactions create color, why and how our eyes perceive it, and how it changes over time. So I absolutely loved this book. I was captivated from the moment I read this line in the introduction: “Blue is not out there, and it is not inside us, either. The radiant blue of a cornflower is a kind of collaboration between us and the plant.” This refers to how objects that appear blue require certain properties to absorb and reflect particular wavelengths of light, and also reach our eye and transmit signals to our brains in a way that we will interpret as blue. I also think of my work as a dyer as a collaboration with plants: I don’t “make” blue, but rather work together with indigo plants to reveal it on textiles. Understanding how that happens is a never ending journey.

Thanks for reading! This newsletter is coming out a few weeks later than I had planned, it’s been a busy month for a variety of reasons. Because of that my website and social media aren’t completely up to date either, although I’m working on it. But the yarn and scarves pictured here are all available, if you see something you like please send me a message for more info! And I’d love to hear about your experiences with blue in the comments.

I do have one more clue to the mystery of the failed vat! As an aside in a Feedback Friday that was otherwise unrelated to indigo, Natalie Stopka mentioned that calcium hydroxide has a shelf life of about a year and should be stored in an airtight container. Mine was definitely older than a year and stored in a plastic bag with a rubber band, which may explain why my vat wasn’t reducing properly.

Singing the Blues by John Marshall taught me how fresh indigo works and has so much information on working with fresh indigo